The global transition toward a sustainable, decarbonized energy system hinges on the development of technologies capable of storing and utilizing clean energy with high efficiency and zero emissions. While battery-electric technology has dominated the passenger vehicle market, Hydrogen Fuel Cells (HFCs) are rapidly emerging as the superior solution for heavy-duty transportation, long-haul logistics, industrial applications, and grid-scale energy storage.

Once relegated to the realm of expensive, futuristic concepts, HFC technology is now on the cusp of a major commercial breakthrough, driven by advancements in material science, plummeting manufacturing costs, and strategic governmental infrastructure investment. This imminent transition promises to unlock hydrogen’s immense potential as the versatile, clean fuel of the future, finally challenging the dominance of fossil fuels in the world’s most demanding sectors.

This extensive guide delves into the core technical breakthroughs propelling HFCs into commercial viability, analyzes the critical challenges surrounding the production and distribution of hydrogen (the “color” debate), explores the transformative applications across various high-impact industries, and outlines the essential public and private sector strategies needed to fully realize the hydrogen economy.

The Technical Leap: How Modern Fuel Cells Win

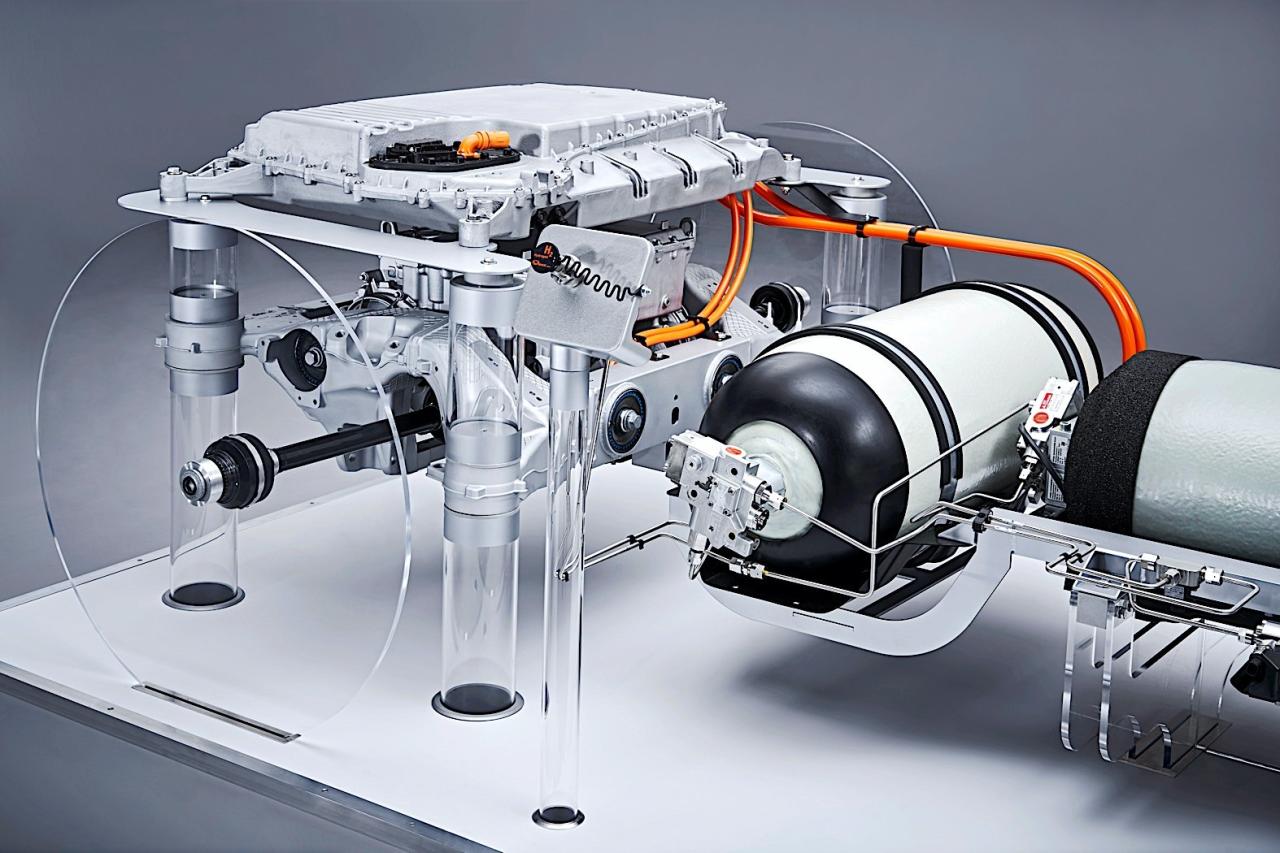

The modern HFC is a sophisticated device that combines hydrogen and oxygen to produce electricity, with the only byproduct being pure water. Recent breakthroughs have centered on improving efficiency, durability, and most crucially, reducing the reliance on costly catalyst materials.

1. Proton Exchange Membrane (PEM) Technology

The Proton Exchange Membrane Fuel Cell is the current standard for mobility and is the focus of most commercial research.

- Mechanism of Action: Hydrogen gas () is channeled to the anode, where a catalyst separates the hydrogen atom into a proton () and an electron (). The proton passes through the PEM (the core breakthrough material), while the electron travels through an external circuit, generating electricity. The proton then combines with the electron and oxygen () at the cathode to form water ().

- Catalyst Optimization (The Cost Barrier): Historically, PEM fuel cells required large amounts of Platinum to catalyze the reactions efficiently. New research focuses on reducing the Platinum loading or replacing it entirely with cheaper, more abundant materials like iron, cobalt, or specialized polymer structures. This reduction in the “platinum cost per kilowatt” is the single most important factor driving cost parity with diesel engines.

- Enhanced Durability: New PEM materials are designed to resist chemical degradation (membrane drying or flooding) and withstand frequent start-stop cycles, extending the operational lifespan of the fuel cell stack to match or exceed that of a conventional internal combustion engine.

2. Solid Oxide Fuel Cells (SOFCs)

SOFCs operate at much higher temperatures and are designed for stationary power generation and large industrial uses, offering distinct advantages.

- High-Temperature Efficiency: Operating at temperatures between and , SOFCs can achieve higher energy conversion efficiencies (up to 60%) than PEM cells. The high heat output can also be captured in a combined heat and power (CHP) system, further increasing efficiency.

- Fuel Flexibility: A major advantage of SOFCs is their ability to run not just on pure hydrogen, but also on natural gas, biogas, or even ammonia, making them highly versatile for transitioning industrial facilities away from fossil fuels without immediate, massive infrastructure changes.

- Non-Precious Catalyst: Due to the high operating temperature, SOFCs do not require expensive platinum catalysts, instead using ceramic materials (like yttria-stabilized zirconia), drastically reducing manufacturing cost and complexity for large-scale applications.

The Hydrogen Supply Challenge: The Color Conundrum

The ultimate sustainability of HFCs depends entirely on how the hydrogen itself is produced. The industry uses a “color code” to define the production method, highlighting the critical shift needed toward clean sources.

1. The Dirty Hydrogen (Brown and Gray)

The majority of hydrogen produced today is derived from fossil fuels, which defeats the zero-emission goal.

- Gray Hydrogen: Produced through Steam Methane Reforming (SMR), where natural gas (methane) is reacted with high-temperature steam. This process is highly carbon-intensive, resulting in large emissions.

- Brown Hydrogen: Derived from coal gasification. This is the least clean method and is responsible for significant greenhouse gas emissions and air pollution.

2. The Transitional Hydrogen (Blue and Pink)

These methods represent steps toward decarbonization but are not entirely emission-free.

- Blue Hydrogen: Produced via SMR, but the emissions are captured and stored underground through Carbon Capture and Storage (CCS) technology. While significantly cleaner than Gray Hydrogen, its long-term viability depends on the permanence and cost of CCS.

- Pink Hydrogen: Produced using electrolysis powered by nuclear energy. This is very low-carbon but relies on the controversial and capital-intensive nuclear power industry.

3. The Sustainable Future (Green Hydrogen)

Green Hydrogen is the only truly zero-emission solution and the focus of the current technological breakthrough efforts.

- Electrolysis Powered by Renewables: Green Hydrogen is produced by using electrolysis (splitting water into hydrogen and oxygen) powered exclusively by renewable electricity (solar, wind, or hydro).

- Cost Reduction Breakthroughs: The primary cost of Green Hydrogen is the capital expenditure of the electrolyzer and the price of renewable electricity. Breakout success in alkaline and PEM electrolyzer efficiency, coupled with the rapid decline in solar and wind costs, is rapidly pushing Green Hydrogen toward cost parity with Blue Hydrogen.

- Gigafactories for Electrolyzers: Global investment in manufacturing large-scale electrolyzer gigafactories is expected to drive down capital costs by over 50% in the next five years, making Green Hydrogen production commercially scalable worldwide.

Applications: Where Hydrogen Dominates

Applications: Where Hydrogen Dominates

HFC technology is uniquely positioned to solve the energy storage and range challenges faced by high-demand sectors where heavy batteries are impractical.

1. Heavy-Duty Transportation and Shipping

This sector offers the clearest and most immediate path for HFC dominance.

- Long-Haul Trucks (The Range Advantage): HFC trucks can achieve ranges of 500 to 800 miles and can be refueled in 10-15 minutes, mimicking the operational profile of diesel trucks. Battery-electric trucks require significantly longer charging times and struggle with range when hauling maximum payloads.

- Maritime and Rail: Fuel cells offer a zero-emission solution for container ships and long-distance freight trains, where the size and weight of batteries needed for multi-day trips are prohibitive. Hydrogen-powered ships can carry more cargo and travel further.

- Port and Forklift Operations: The constant operation and enclosed environment of ports and warehouses benefit immensely from HFC forklifts and utility vehicles, which offer quick refueling and zero local emissions, contributing to worker health.

2. Grid-Scale Energy Storage (The Seasonal Buffer)

HFCs provide a necessary solution for storing massive amounts of renewable energy generated during off-peak times.

- Power-to-Gas (P2G): When solar and wind generation exceeds grid demand, the excess electricity is used to produce Green Hydrogen via electrolysis. This hydrogen can then be stored in large underground caverns or tanks for months.

- Re-electrification: When electricity demand peaks or renewable output is low (e.g., winter or nighttime), the stored hydrogen is fed back into SOFCs or turbines to generate dispatchable, clean power, providing seasonal energy storage—a function batteries cannot efficiently handle.

3. Aviation and Industrial Feedstock

These are the long-term, high-impact markets for hydrogen.

- Synthetic Fuels (Power-to-Liquids): Hydrogen can be combined with captured to create synthetic, zero-carbon jet fuel (e-kerosene), providing the only viable long-term pathway for decarbonizing long-haul flight.

- Decarbonizing Industry: Hydrogen is a key feedstock for manufacturing chemicals (ammonia, methanol) and is critical for high-heat industrial processes like steel and cement production. Green Hydrogen can replace fossil fuels in these processes, eliminating massive industrial emissions.

The Infrastructure and Commercialization Hurdle

The primary barrier to HFC market dominance is the lack of ubiquitous, cost-effective hydrogen infrastructure.

1. Distribution and Storage Challenges

Hydrogen is extremely light and energy-dense by weight, but bulky and difficult to handle by volume.

- Compression and Liquefaction: Hydrogen must be either highly compressed (700 bar) or cryogenically liquefied ( at ) for transportation and storage. Both processes are energy-intensive and costly.

- Pipelines and Safety: Building new hydrogen pipelines is expensive, and converting existing natural gas lines presents material and safety challenges. Public perception of hydrogen safety remains a critical hurdle, requiring rigorous standards and public education.

- Refueling Station Economics: HFC refueling stations are significantly more complex and expensive to build than battery charging stations. Initial demand requires government or consortium subsidies to make the capital investment viable until fleet usage achieves economies of scale.

2. Public-Private Sector Strategy

Overcoming the infrastructure challenge requires coordinated strategic investment.

- Anchor Fleets and Corridors: Initial investment must focus on establishing high-volume “hydrogen corridors” along major freight routes, supported by large “anchor fleets” of corporate trucks, to guarantee a baseline demand that justifies station investment.

- Harmonized Standards: Global standardization of hydrogen purity, refueling protocols (e.g., pressure and nozzle types), and safety regulations is essential to facilitate international trade and investment.

- Policy Support (Production Tax Credits): Government incentives, such as production tax credits (like those in the US Inflation Reduction Act), are crucial to temporarily lower the price of Green Hydrogen until technological scaling achieves natural cost parity.

Conclusion

Conclusion

The breakthrough is no longer a question of if, but when. Driven by remarkable success in reducing the reliance on platinum, the exponential decline in renewable energy costs, and the development of large-scale electrolyzer manufacturing, Hydrogen Fuel Cells are poised to shift from a high-cost novelty to a mass-market, scalable clean energy solution. While infrastructure challenges remain formidable, the unique advantages of HFCs—long range, quick refueling, and high energy density—make them indispensable for decarbonizing the heavy-duty and industrial sectors. The confluence of technological maturity and massive, strategic public-private investment signals that the hydrogen wave is not a distant vision, but a near-term reality that will fundamentally transform the global energy landscape and secure the future of clean, high-performance power.